| Standard Products

While we are geared to make custom metal parts, there are certain families of parts

that we offer as standards. Fotofab standard products give you a fast and inexpensive

solution to your precision thin metal needs since they require no phototooling costs.

RF Shields Designed specifically for your prototype shielding requirements,

we offer a wide variety of RF shield sizes that are available for immediate shipping

and no phototooling charges. The standard shields that we offer are the perfect

solution for preliminarily determining the effect of shielding over your board-level

components. Click

Here. RF Shields Designed specifically for your prototype shielding requirements,

we offer a wide variety of RF shield sizes that are available for immediate shipping

and no phototooling charges. The standard shields that we offer are the perfect

solution for preliminarily determining the effect of shielding over your board-level

components. Click

Here.

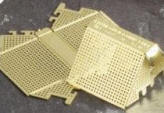

Crystal Modular Mask System Manufacturers of piezo-electro crystals

have relied on Fotofab for years to provide a complete Crystal Modular Mask System

for base-plating their crystals. Check out pre-tooled line of 16 and 36-opening

masks, spacers, frames and magnetic bases.

Click Here. Crystal Modular Mask System Manufacturers of piezo-electro crystals

have relied on Fotofab for years to provide a complete Crystal Modular Mask System

for base-plating their crystals. Check out pre-tooled line of 16 and 36-opening

masks, spacers, frames and magnetic bases.

Click Here.

Electronic Packaging Lids Fotofab can precisely fabricate lids for your

microelectronic or fiber optic components. We offer no tooling on many sizes of

step lids for your electronic package.

Click Here. Electronic Packaging Lids Fotofab can precisely fabricate lids for your

microelectronic or fiber optic components. We offer no tooling on many sizes of

step lids for your electronic package.

Click Here.

CONTACT INFORMATION

Fotofab

3758 West Belmont Avenue

Chicago, IL 60618 USA

Phone 773.463.6211

Fax 773.463.3387

Web Site: http://www.fotofab.com

E-Mail:

sales@fotofab.com

Text and images copied from Fotofab

copyrighted

material.

|

Custom Products

If

our standard products do not meet your requirements, then be sure to take advantage

of our low tooling cost and quick lead-time on custom parts. We can make custom

parts in as few as 72 hours! If

our standard products do not meet your requirements, then be sure to take advantage

of our low tooling cost and quick lead-time on custom parts. We can make custom

parts in as few as 72 hours!

- Metal Stamping

- Metal Fabrication

- Precision Machining

Fotofab's comprehensive metal fabricating capabilities allow our customers

to receive production-quality, metal stamping and other custom parts in as few as

three days. And a minimum new part order can be tooled and fabricated for a few

hundred dollars, regardless of part configuration or complexity.

Our valued customers are an integral part of the following hardware manufacturing

industries: medical, aerospace/defense, telecom, consumer electronics, process sensing

and control, test and measurement, frequency control and automotive electronics.

Our portfolio of customers by industry highlights a few of the hundreds of companies

that entrust Fotofab with their metal parts needs.

The applications that you can design and have made using our capabilities range

from apertures to zone alignment plates, are left to your imagination. Consult with

Fotofab's technical sales staff to recommend the most cost-efficient manufacturing

method to fabricate your metal part design to specification.

- Photochemical machining

- Electroforming

- Progressive die stamping

- PEM hardware assembly

- Label/adhesive application

- Tumbling

- EDM

- Laser cutting

|

- Welding

- Soldering

- Engineering consulting

- Forming

- Plating / painting

- Heat treating

- Lapping

- Passivation

- Electropolishing

- Tapping

|

|